PCBA testing is the most critical quality control link in the PCBA manufacturing process and determines the final performance of the product in use.

With the advent of the 5G era, the integration degree of PCBA circuit boards is getting higher and higher, and terminal products such as 5G mobile phones and PADs have almost no test points. Traditional domestic ICT and flying probe testing equipment can no longer meet the online testing requirements of the 5G era; while the flying probe testing equipment from countries in Europe, America, and Japan on the market is very expensive, and the core technology and data are not open to China, and customers cannot conduct secondary development on these equipment.

Currently, the PCBA circuit board industry urgently needs equipment that combines high precision, high speed, and intelligent maintenance functions to meet the rigid requirements of production and maintenance.

To fill the gap in the field of China's multifunctional flying probe testing, IFREE's first high-end multifunctional flying probe testing equipment was successfully rolled off the production line, and the delivery ceremony was held at the Shenzhen R & D Center. IFREE General Manager Shao Yongfeng, Sales Director Zhou Bin, Software Head Huang Liang, and many industry customers attended together.

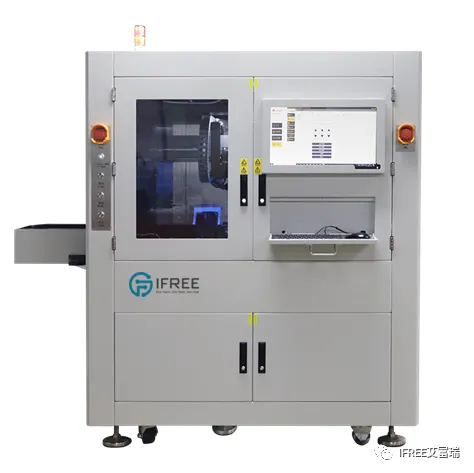

IFREE High-end Multifunctional Flying Probe Testing Equipment

The high-end multifunctional flying probe testing equipment released this time is already IFREE's third-generation product. Through the air suspension motion mechanism, it uses six rapidly moving test probes for free combination to perform performance testing on 5G PCBA products online or offline, fully covering the testing requirements of PCBA, and can achieve static ICT of components and dynamic functional testing of products, including power-on, communication, VI, RF radio frequency, etc.

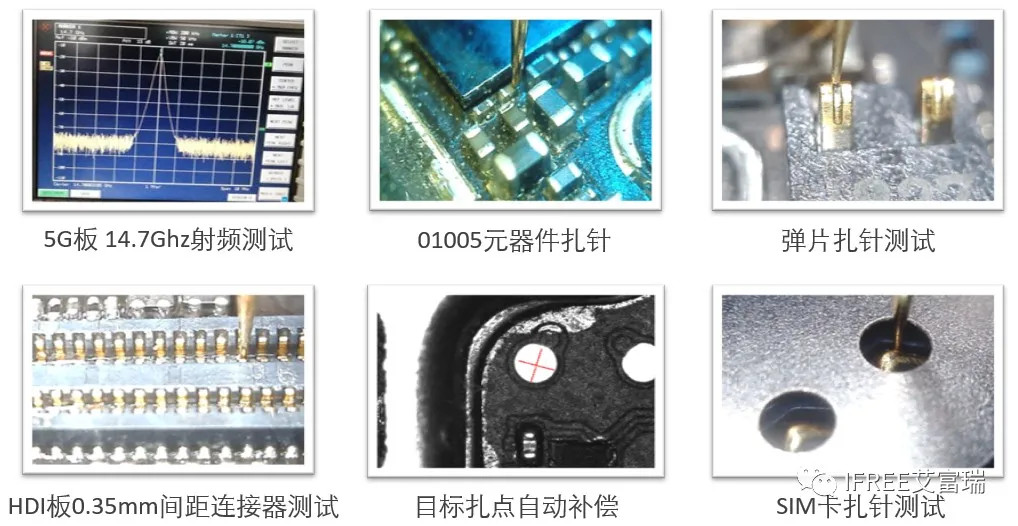

Application Examples of IFREE High-end Multifunctional Flying Probe Testing Equipment

Shao Yongfeng, the General Manager of IFREE, introduced that to meet the testing requirements of the 5G era, the newly launched high-end multifunctional flying probe testing equipment is equipped with the high-speed and high-precision air-floating platform AirTrack and the high-precision programmable UUT power supply independently developed by IFREE, and has successfully integrated the VI curve tester, infrared thermal scanning, and BSCAN, ISP online programming functions.

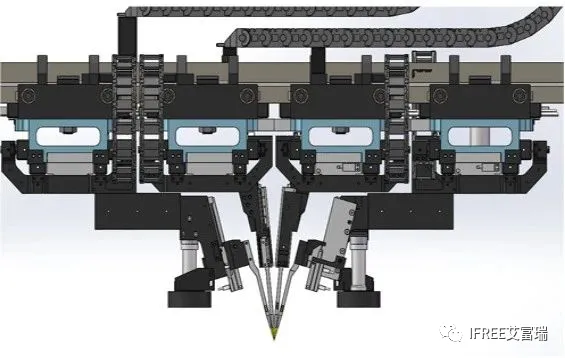

The AirTrack innovatively uses the air suspension principle to historically increase the equipment movement speed to 5m/s, the repeated positioning accuracy can reach 1um, and the dynamic response is up to more than 5g, directly increasing the equipment performance to several times that of traditional equipment.

AirTrack

IFREE has also invented high-precision micro-elastic probes with an ultra-low elasticity of 10 grams, ensuring no damage during component testing. IFREE's pioneering intelligent modes such as testing strategies + dichotomy + circuit fault relationship tree can not only quickly and accurately find problem points, but also test faster and more accurately.

Customized Probes with Minimum Spacing and Minimum Elasticity

In addition, IFREE's high-end multifunctional flying probe testing equipment integrates Vayo's DFT software. IFREE has established a global partnership with Shanghai Vayo Information Technology Co., Ltd. and has become a distributor of VayoPro brand series software products of Shanghai Vayo Information Technology Co., Ltd. Shanghai Vayo Information Technology Co., Ltd. is a leading and high-quality industrial software supplier integrating PCBA process design simulation and manufacturing. Currently, Vayo's NPI series software products have been applied by more than 400 enterprises in more than 20 countries and regions around the world.

IFREE is controlled by Shenzhen Orange Automation Co., Ltd. and is located in the free trade zone of Suzhou Industrial Park, focusing on future global layout and operation.

Shao Yongfeng, the Chairman of IFREE, said that IFREE's business direction highly coincides with Suzhou's industrial foundation, and IFREE will be based in Suzhou, rely on the high-precision flying probe testing platform, create value, deliver value, and share value, facing the world.