IFREE manufactures multifunctional flying probe testing equipment in China, which features high precision and high speed. The company currently has single-sided four-needle flying probe equipment, double-sided six-needle flying probe equipment, and double-sided eight-needle flying probe equipment. They can be widely applied in various application scenarios such as 5G communication, servers, laptops, automotive electronics, medical electronics, aerospace, etc., and provide testing and solutions in these scenarios.

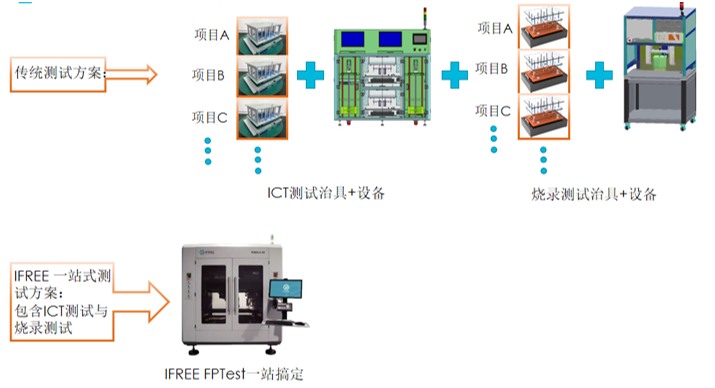

The traditional testing process in general factories is: ICT testing → FCT programming testing → board separation. Among them, ICT testing includes ICT machines and fixtures. ICT fixtures are made based on PCBA CAD files, and different types of PCBA products require different ICT fixtures to be made; FCT programming testing includes programming equipment and programming fixtures, and different PCBA products require different programming fixtures to be made. To test different PCBA products, a large number of ICT testing fixtures and FCT programming fixtures need to be made. The production and debugging cycle of testing fixtures is relatively long. For example, for a new PCBA product to conduct ICT testing, ICT program development and testing fixture production are required. ICT program development takes 1 week, fixture hardware production takes 2 weeks, and program and fixture debugging takes 2 weeks, so the total lead time is 5 weeks. Not only is the cycle long, but also different fixtures need to be replaced manually, which is time-consuming and laborious, and a large number of testing fixtures will also increase storage costs.

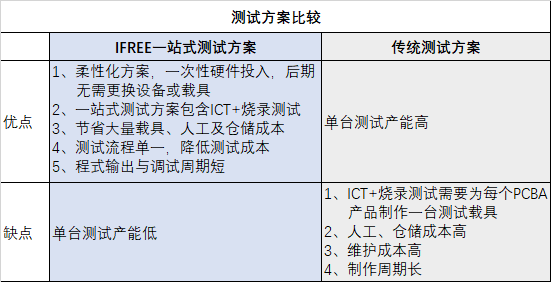

In order to optimize the testing process and reduce testing costs, IFREE launches a one-stop testing solution, integrating ICT and programming testing, reducing the investment in testing fixtures and programming equipment, and not changing fixtures during model change. The following figure shows the introduction of IFREE's one-stop testing solution and the comparison of advantages and disadvantages with traditional testing solutions:

The IFREE one-stop testing solution only needs to import PCB CAD files to output LCR testing programs, and program production takes 4 hours; importing testing strategies and related configurations takes 1 hour; LCR debugging takes 4 hours; programming configuration takes 1 hour. The total time for importing a PCBA product for testing is 10 hours, which greatly saves the time for program production and debugging in the early stage of testing.

The following is an actual one-stop testing case customized for a customer. The customer's testing requirements integrate ICT and programming testing, and the specific requirements are as follows:

First, conduct LCRD testing, and automatically switch to programming testing after the testing is completed. The programming testing is divided into two steps. The first step is to program the hex file first; the second step is to write the board SN and then verify, and output the Log file after the testing is completed.

The IFREE one-stop testing solution recommendation: In order to increase testing capacity, we recommend using six-needle equipment for LCRD + parallel programming testing, that is, programming 4 boards simultaneously at a time.

The simple schematic diagram is as follows: