Mobile communications, Servers

Industry Status

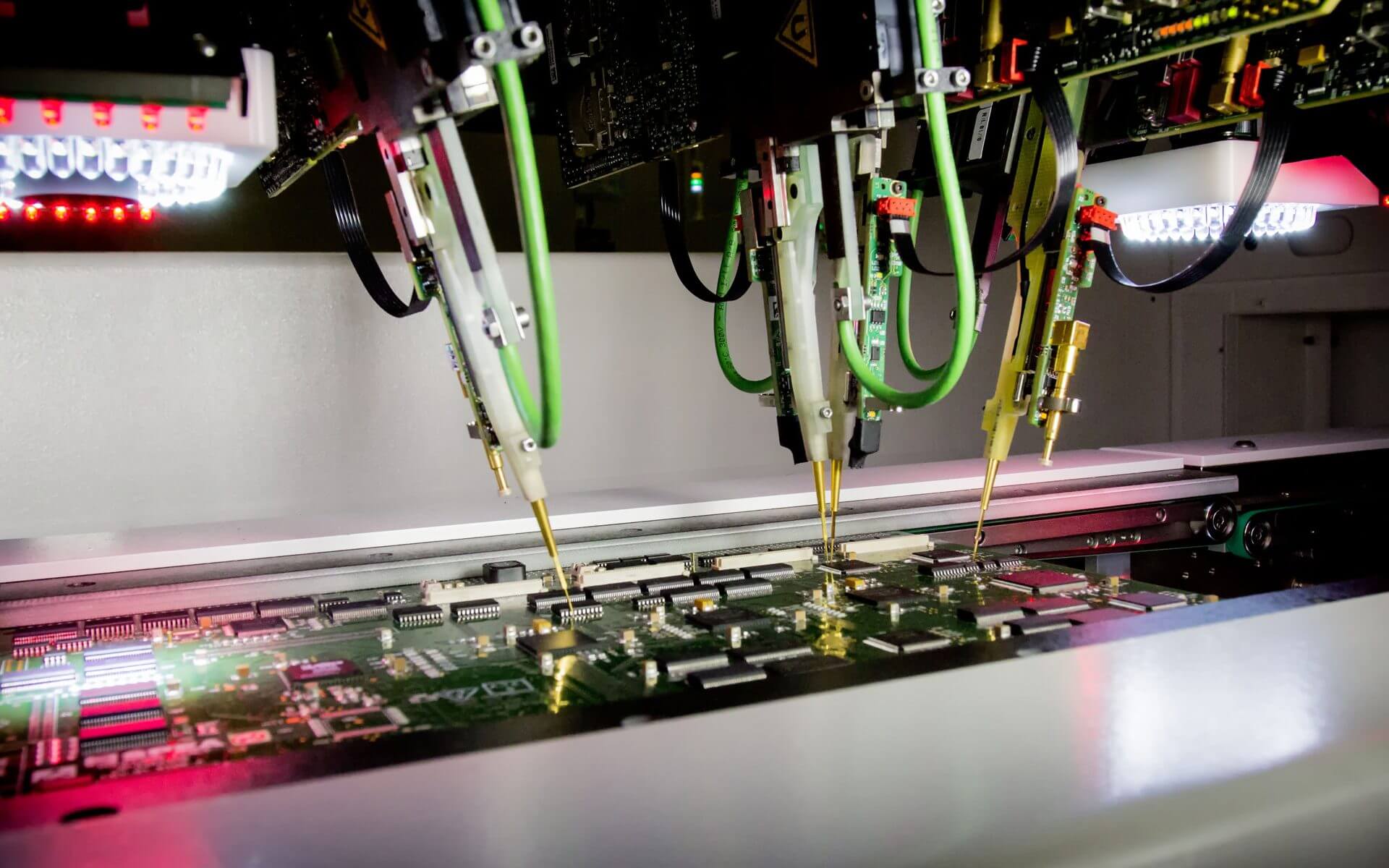

There are thousands of devices in a few square centimeters on the circuit boards of smart phones and mobile device electronics. During the testing and calibration phase of the production process, it is often necessary to test each component and function. However, these tests often take a lot of time, and the various instruments used for testing are also relatively expensive, thus becoming a bottleneck restricting the production efficiency of manufacturers in the mobile phone and communication fields.

Solution Advantages

IFREE flying probe test equipment can precisely contact the smallest components and test every component and function, including wireless communication protocols (such as 5G), sensors, touch displays and buttons. IFREE flying probe test equipment can easily handle the smallest microelectronics and the largest circuit boards. It is very suitable for testing small modules as well as large telecommunication components, including RF circuits and pin connectors.

Solution Features

Complete test rate

Provides the highest test coverage, and the testable objects include pads, test points, part electrodes, connectors, and heterogeneous components

No probe marks

Extremely small test nodes, can test 008004 packages as low as 0.125mm

Reverse Engineering

Complies with ISO17025 and meets the general requirements of laboratories for calibration and testing capabilities

Wide Compatibility

It can be used directly between different software versions without tedious reconstruction and debugging, avoiding software compatibility issues caused by equipment upgrades

Product life cycle support service

IFREE team has many years of industry-related experience and can meet the long-term support requirements of customers in the military, aerospace, and defense industries for equipment use

Solution Application

Mobile phone

5G communication base station