Automotive electronics, Medical electronics

Industry Status

Automotive electronics manufacturers require zero defects in their electronic products to ensure that the products can work properly throughout the life cycle of the car (10 to 20 years).

Solution Advantages

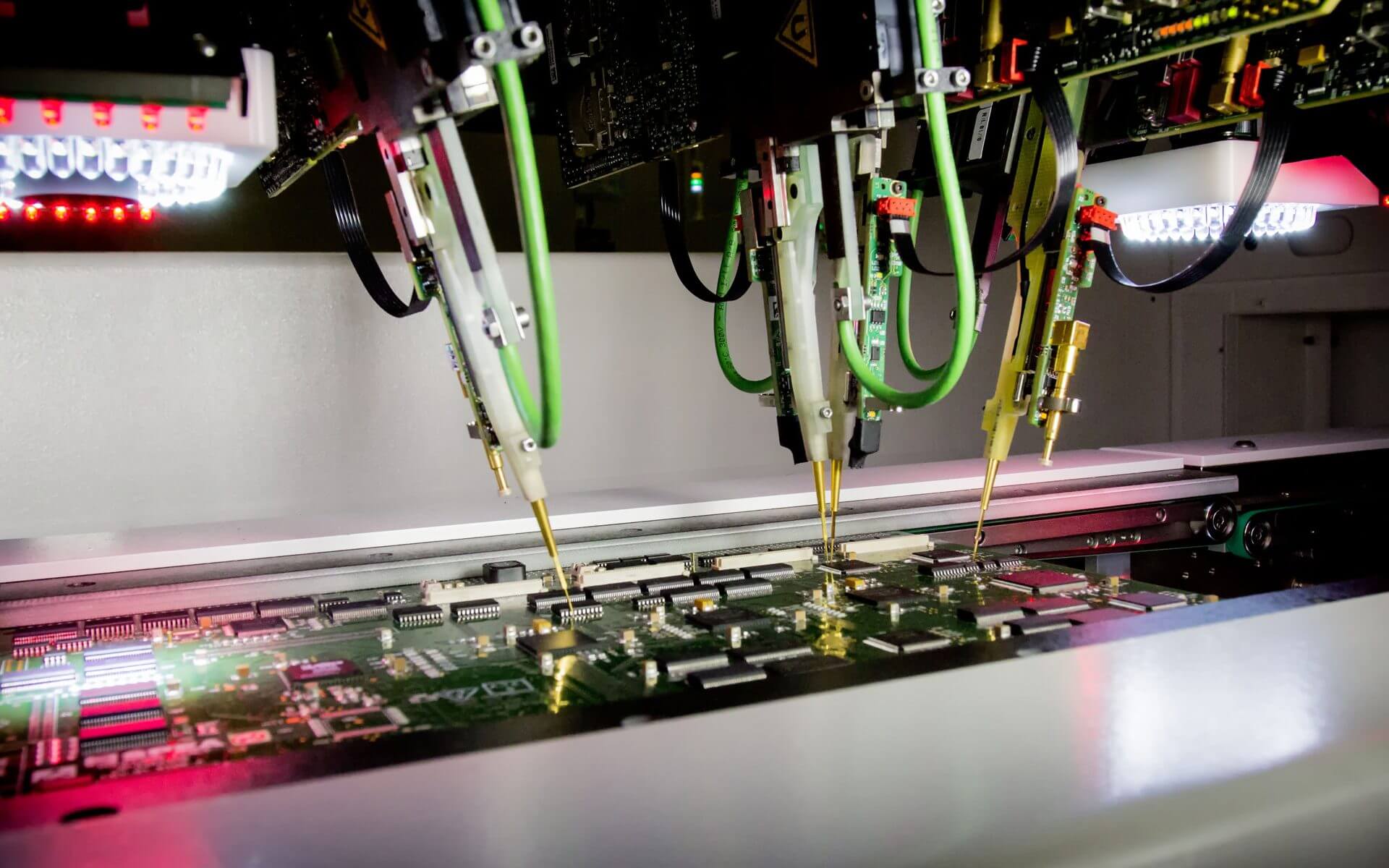

As a highly integrated test equipment, IFREE flying probe test equipment includes multiple test technologies such as ICT/FCT/VI/ISP/BSCAN, providing customers with a solution to prevent product failures at the lowest test cost.

Solution Features

Complete test rate

Provides the highest test coverage, and the testable objects include pads, test points, part electrodes, connectors, and heterogeneous components

No probe marks

Extremely small test nodes, can test 008004 packages as low as 0.125mm

Reverse Engineering

Complies with ISO17025 and meets the general requirements for the laboratory's calibration and testing capabilities

Traceability

Complete traceability system, system software can record and analyze test results, providing a powerful tool to monitor product quality

Digital Factory

Flying probe test is efficient and flexible, adapts to diverse needs, and can be fully integrated into the digital factory

Solution Application

Power System Electronics

Power Management

Wearable Electronic Devices

Lighting system

Multimedia

MEMS and sensors

(accelerometers, gyroscopes, microscanners, pressure sensors, temperature sensors, tpm sensors)